Fuelled By

Glenfiddich

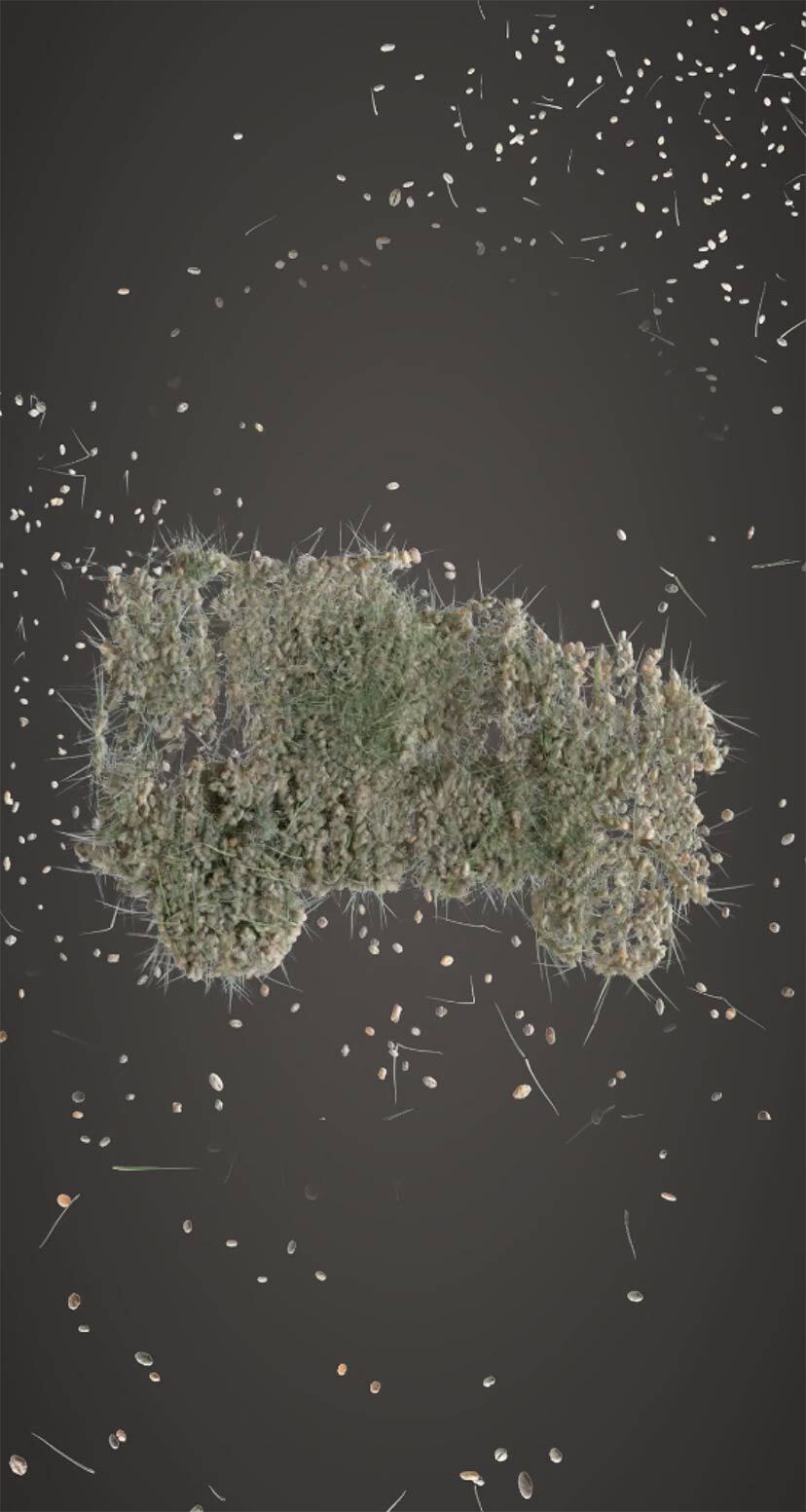

In 2021, we launched a pioneering ‘closed loop’ sustainable transport initiative that made us the first global spirits brand to run its delivery fleet on green biogas made from the residues of its own distilling process.

Using a unique technology developed by our parent company William Grant & Sons, the Glenfiddich distillery converts its production wastes and residues into an Ultra-Low Carbon Fuel (ULCF) gas that produces minimal carbon dioxide and other harmful emissions.

Stuart Watts, William Grant & Sons’ distilleries director: “It has taken more than a decade for Glenfiddich to become the first distillery to process 100% of its waste residues on its own site, then to be the first to process those residues into biogas fuel to power its trucks, and finally to be the first to install a biogas truck fuelling station supplied by our on-site renewable energy facility.

“Across the entire production lifecycle, the biogas reduces carbon dioxide (CO2e) by over 95% and other harmful particulates and greenhouse gas emissions by up to 99% when compared to diesel and other fossil fuels. Each truck will displace up to 250 tonnes of CO2e annually, which has the same environmental benefit as planting up to 4,000 trees every year.”

The ‘Fuelled by Glenfiddich’ breakthrough is an example of the brand’s actions to reduce the environmental impact of its production process. It is one of a range of sustainability activities taking place across William Grant & Sons’ wider business in line with the Scotch Whisky Association (SWA)’s roadmap to achieve targets set out under the United Nations’ Sustainable Development Goals.